Specifications

An Industrial Effluent Treatment Plant is a facility designed to treat wastewater generated by industrial processes before it is discharged into the environment. Industrial effluent contains various pollutants, chemicals, and contaminants that can be harmful to the environment and public health if not properly treated. The main purpose of an Industrial Effluent Treatment Plant is to remove or reduce the concentration of pollutants present in the industrial effluent to acceptable levels, ensuring that the discharged water meets the regulatory standards. Our products are mostly used in the Pharmaceutical & Chemicals Industries and can be made up of varied materials as per customers’ needs.

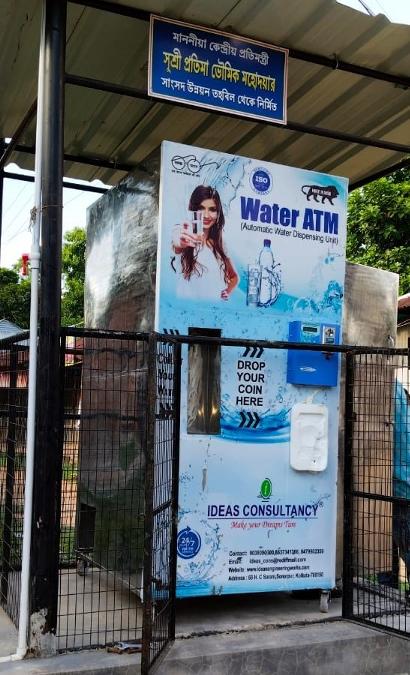

By treating industrial wastewater, it helps prevent the contamination of natural water bodies such as rivers, lakes, and groundwater, preserving the ecological balance and protecting aquatic life. The best Industrial Effluent Treatment Plants are manufactured, exported, and supplied by Ideas Engineering Works across Asia and the Gulf nations. We are a Kolkata-based company and were established in 2009 and we also provide services for them. Due to our products’ durability and efficacy, it is deeply trusted by our customers.

- By treating industrial wastewater before discharge, the plant prevents harmful pollutants from contaminating water bodies, soil, and air.

- Advanced technologies like membrane filtration, chemical precipitation, activated carbon adsorption, reverse osmosis, and ultraviolet disinfection are used

- Some industrial processes produce wastewater that contains valuable resources or chemicals. Industrial Effluent Treatment Plants can extract those chemicals

| Product/Service Name | Industrial Effluent Treatment Plant |

| Brand Name | Ideas Engineering Works |

| Plant Type | Effluent Treatment Plants (ETP) |

| Application | Industrial |

| Installation Service | Yes available |

| Water Source | Industrial Wastewater, Sewage water |

| Capacity Inlet Flow Rate(m3/day) | Depends on the project/clients requirement |

| Materials Used | Mild steel (MS), FRP, Stainless Steel |

| Treatment Method Used | Mixed Bed Bio Reactor(MBBR), Sand Filtration, Activated Charcoal treatment (Adsorption), Ozonisation (Chemical Oxidation), Ultra Filtration (UF), Reverse Osmosis (RO) and evaporation (If required) |

| Power Source | Electrical |

| Voltage Required | 240 to 480V |

| Type Of Control | In switch/panel or equivalent system |

| Installation Time/Period | 5 to 15 Days (Depending on the project requirement) |

| Warranty | On mechanical items |

| Servicing and Maintenance | Yes Available (As Per project requirement condition) |

| Transportation Charges | Depends on project location and requirement |

| Payment Modes | NEFT, RTGS, Cheque, IMPS, Bank Transfer (Only in Banking modes) |

| Installation Period/Time | Depends on project requirement and location |

| Main Domestic Markets | All over India |

| Country Origin | India |

| Export Areas | Nepal, Bangladesh and other neighbor countries |